对于过程可视化而言,全新版本的 WinCC 由于采用了新的标准,可为您当前应用和今后进一步的扩展提供更优越的性能,更大的灵活性和更高的效率。

SIMATIC WinCC 向用户展现了过程可视化的崭新前景:

·持续的延展性现在,最多可以组态12 个有冗余功能的 WinCC 服务器,每个服务器最多可以组态32个WinCC 客户机

·增强的 Web 技术WinCC 客户机上的 Web 服务器用作数据集中器,安全性更高

·基本系统中的 Historian兼具高性能的过程数据归档功能和信息交换功能

·用于 IT 和商务集成的最优软件信息交换(Historian)、客户机和评估工具以及用于集成的开放性接口

·新的开放性标准实现配置自动化的 VBA简单易用的运行时脚本语言 VBScript通过 OPC A&E 的消息通过 OPC HDA 访问归档数据通过 OLE-DB 访问 WinCC 数据库

·全新选件用于 IT 及商务集成的选件,以及用于符合 FDA 21 CFR Part 11 应用的选件以及更多其它选件...

新版本技术亮点:

更安全的系统

WinCC作为后台服务运行,可将IO服务器、数据归档服务器和Web服务器放置在安全数据中心,用户无需登录即可运行

集成中央用户管理工具 SIMATIC Logon,可以使用Windows用户验证机制

使用无IE的客户端,增强系统安全性

更好的性价比

最大提供 256K点外部IO,支持超大系统

256、1K点升级为512、2K点

WinCC作为后台服务,运行效率更高

Web客户端支持FDA

面向全球化设计,文本发布器,多语言切换、组态工具

更美观、更简便的用户界面设计

支持Windows Vista风格,真彩、渐进色、光影效果等

项目界面风格统一定义、定制

支持面板功能,基于对象的开发模式,组态工作可重复使用,节省组态时间

更开放的系统

第三方驱动支持(Modbus TCP、Ethernet/IP)

支持.Net 和 XMAL 控件,.Net支持WinCC OLE/DB

可作为系统平台软件,集成其它子系统

功能特色:

集成组态

- 从微型面板到 PC

- 多设备项目和设备开关

面向解决方案

- 智能工具,例如图形导航和移动的图形化组态

简单、高效

- 易于上手

- 功能强大

HMI 模块

- 可任意定义、重复使用,可集成修改

TIA 集成

- STEP7 V5.3

- iMap V 2.0

- Scout

创新的 HMI 概念

- 分布式操作员站

- 集中访问本地站

- 小型控制室解决方案

- 工厂范围内的信息流,从面板到办公室

服务和诊断

- 通过 Web进行维护

- 远程诊断和下载

- 自动发送电子邮件

兼容性和移植

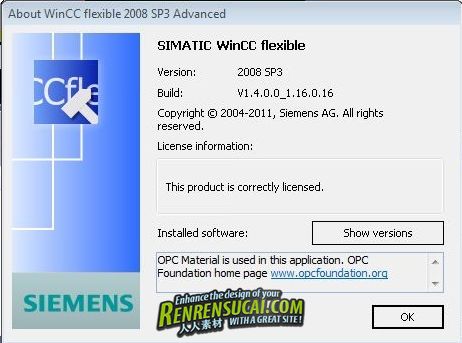

Siemens SIMATIC WinCC Flexible 2008 SP3 32bit & 64bit

SIMATIC WinCC flexible is the proven HMI software for flexible implementation in machine- and process-oriented applications, across all industries.

About Siemens AG

Siemens AG is a German engineering conglomerate, the largest of its kind in Europe. Siemens has international headquarters located in Berlin, Munich and Erlangen. The company has three main business sectors: Industry, Energy, and Healthcare; with a total of 15 divisions. Worldwide, Siemens and its subsidiaries employ approximately 420,800 people in nearly 190 countries and reported global revenue of 76.651 billion euros for the year of 2009. Siemens AG is listed on the Frankfurt Stock Exchange, and has been listed on the New York Stock Exchange since March 12, 2001.

Overview

SIMATIC WinCC flexible stands for maximum configuration efficiency. Just some examples: It features numerous libraries with pre-installed objects and intelligent tools. The runtime software also provides operating functions and a reporting system, and both the engineering and runtime software can be expanded functionally or to meet industry-specific demands with WinCC flexible options.

System features

Maximum engineering efficiency – in all phases of the lifecycle of the machine and plant.

With SIMATIC you rely on an integrated engineering environment. Efficient software supports you over the complete lifecycle of your machine or plant – from the planning and design stages through configuring and programming as far as commissioning, operation and upgrading. With its integration capability and harmonized interfaces, SIMATIC software supports a high degree of data consistency – throughout the entire engineering process.

Maximum data transparency on all automation levels – based on proven standards.

SIMATIC creates the foundations for unlimited integration in communication – and thus for maximum transparency on all levels, from the field and control level to the operations management level all they way up to the corporate management level. SIMATIC relies on international, cross-vendor standards which can be combined flexibly: PROFIBUS, the global No. 1 fieldbus, and PROFINET, the leading Industrial Ethernet standard

Minimization of downtimes – through efficient diagnostic concepts

All SIMATIC products feature integrated diagnostic functions with which a fault can be identified and eliminated to provide increased system availability. Even with larger plants, the Maintenance Station provides you with a uniform view of the maintenance-relevant information of all automation components.

Protection of personnel and machines – within the framework of an integrated complete system

SIMATIC Safety Integrated offers TUV-certified products, which facilitate compliance with relevant standards: IEC 62061 up to SIL 3, EN ISO 13849-1 up to PL e, as well as EN 954-1. Due to the integration of safety technology in standard technology, only one controller, one I/O, one engineering, and one bus system are required. Thus the system advantages and comprehensive functionality of SIMATIC are also available for fail-safe applications.

请先收藏,下载地址稍后...

该贴已经同步到 admin的微博 该贴已经同步到 admin的微博 |

/2

/2